To secure, rotate the breaker down and snap it over the Busbar. Installing a Hook-On Breaker: Hooks or snaps over the round rod.Installing a Push-Down Breaker: The breaker notch sits against the rail or a cleat rotate the breaker down on the Busbar and then push down.

#60 amp sub panel wire size code

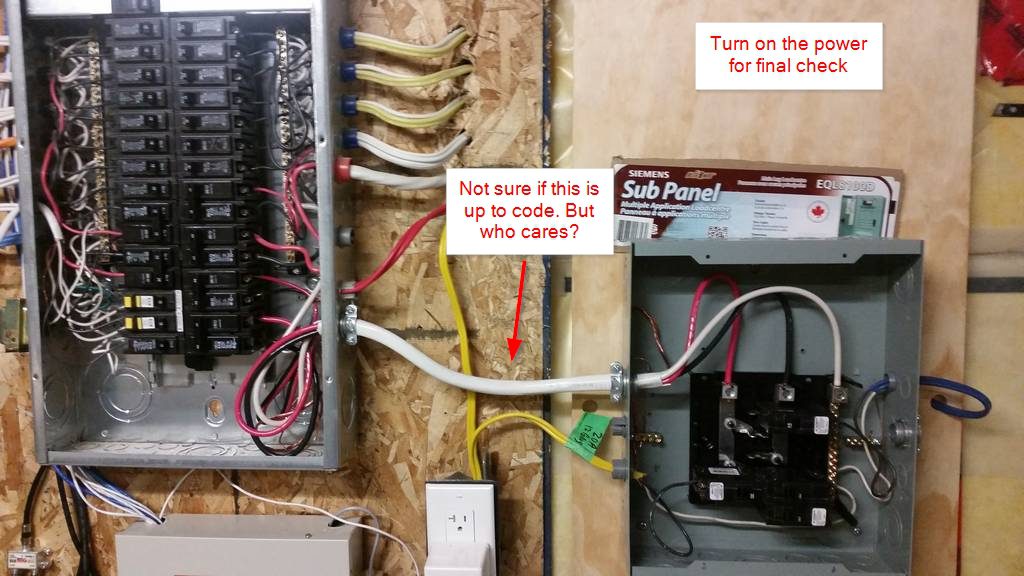

Use Double-Pole Breakers: 208–240-volt breakers must have connected switches so both legs are either on or off (separate single-pole breakers are a code violation).Make Sure Wires Are Tight: Wire insulation should be stripped such that there’s only copper wire under the screw.Once new circuit cables are run into the sub panel, clamp each cable and route the wires for each circuit around the perimeter.Connect the ground wire to the ground bus bar. The red/black wires connect to the hot bus bars, while the neutral (white) wire goes to the main neutral terminal. Cut and strip the feeder wires and connect them to the proper terminals.Then route, cut, and strip the red/black wires and connect them to the feeder breaker. Route neutral and ground wires and connect them to their respective bus bars.Strip enough wire sheathing to attach the wire then remove a knockout slug and clamp the cable in place.Plan the routes for the ground, neutral and black and red hot wires.When mounting the sub panel, make sure it’s about 1 foot away from the main service panel and measure how far each wire will need to travel.The panel must be mounted to a permanent structure and where equipment cannot impact it. They should be placed in a sheltered, shaded area and at least 12 inches above where snow is likely to accumulate. Outdoor sub panels are weather resistant. Mounting must be done so that the cover fits flush against the metal box once the drywall is installed. They must be attached to the structure and not mounted to drywall. Indoor sub panels are usually mounted between 2 x 4 studs and are not weathertight. Always check the product rating to make sure you’re using the correct wires. For a six-space panel used indoors, a 100-amp wire size is needed, while a two-space, outdoor panel can work with a 60, 100, or 200-amp wire. And make sure to use insulated electrical tools to avoid injury. Nonmetallic flexible cables must be used to carry ground wire, while armored steel cable can be used as a grounded connection. Here are the appropriate sizes/amp ratings:Īlways use copper for a ground wire (and never as a neutral wire). Only 600-volt copper wire should be used. Tools you’ll need for installation include a screwdriver, hammer, voltage tester, flashlight, wire strippers, lineman’s pliers, and long-nose pliers.įor materials, you’ll need the sub panel, mounting screws, a feeder cable approved for the application, staples or cable clamps, circuit breakers, and an approved feeder breaker. There is usually no main breaker here, and separate bus bars for neutral and ground wires. The main panel’s feeder breaker works as the main disconnect for the subunit. This component is suited for homes that can’t accommodate tandem circuit breakers, and don’t have room for new breakers. While it’s best to consult with an electrical contractor, here are the basic things you need to know about installing an electrical sub panel.

To connect one to your main service panel, you’ll need a thick three-wire cable. You might need a sub panel if there aren’t enough circuit breakers in your main electrical service panel.

0 kommentar(er)

0 kommentar(er)